SNOW DRAGON’S BEARING FAILURE INVESTIGATION: THE CASE STUDY

At 2018 we got a request to investigate the cause of the intermediate bearing failure (wiping of the bearing bush accompanied by a significant temperature increase) that happened at the Chinese icebreaking research vessel Snow Dragon (雪龙, Xue Long in Chinese) on her way home after Arctic region voyage.

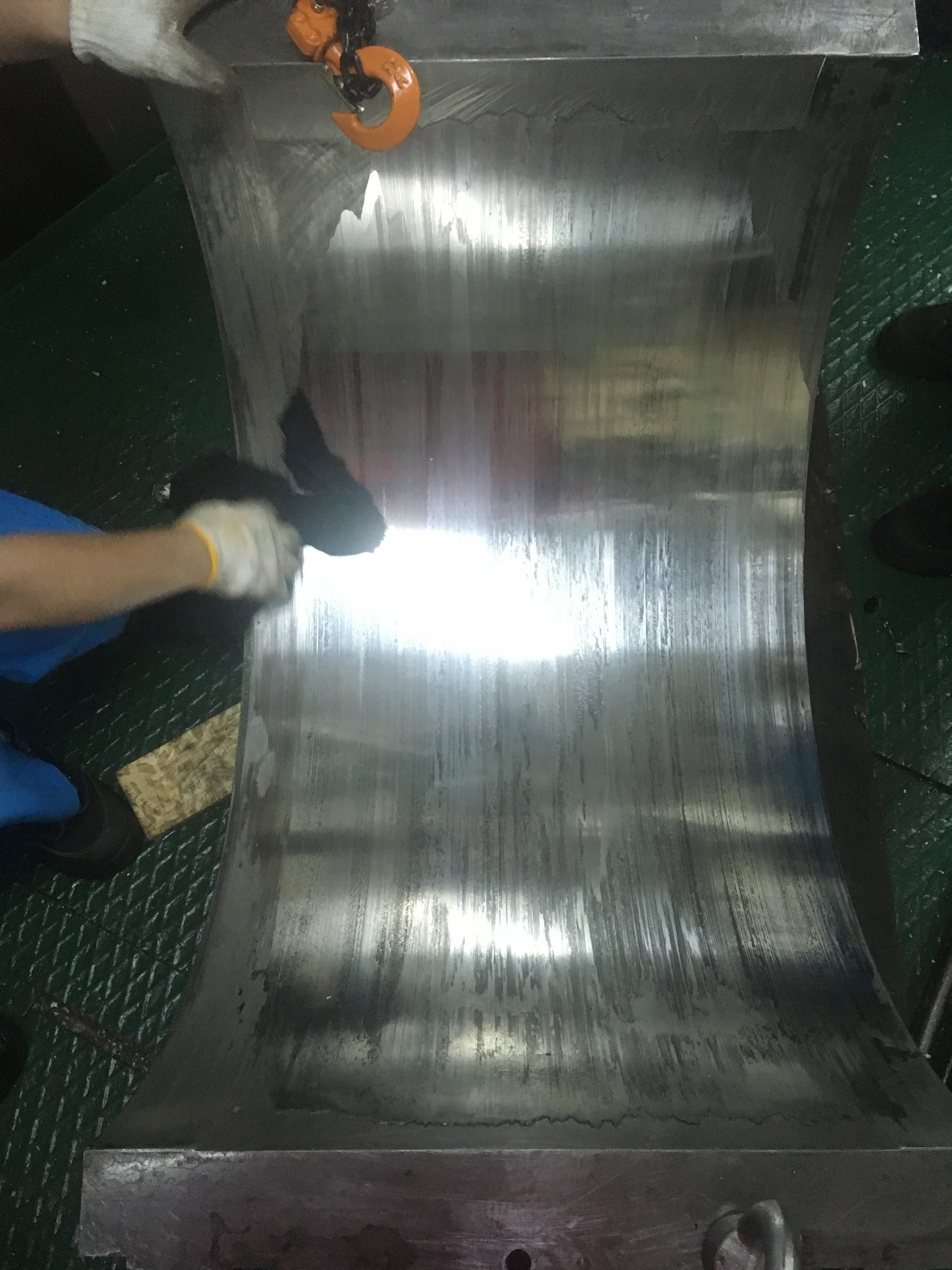

We went to China to have a look at the bearing and to have a round table discussion with the ship crew on board. During the discussion three suggestions concerning the reason of the bearing failure were formulated: oil leakage caused by unknown reason; extreme propeller loads in storm conditions; dynamic bearing loads due to ice induced whirling; and the combination of the above reasons. The first two reasons were discarded by the fact that the crew excluded the oil leakage. Besides, the vessel had been operated for 24 years, even in stormy conditions. The only assumption left to check was bearing overloading due to dynamic loads caused by ice induced whirling.

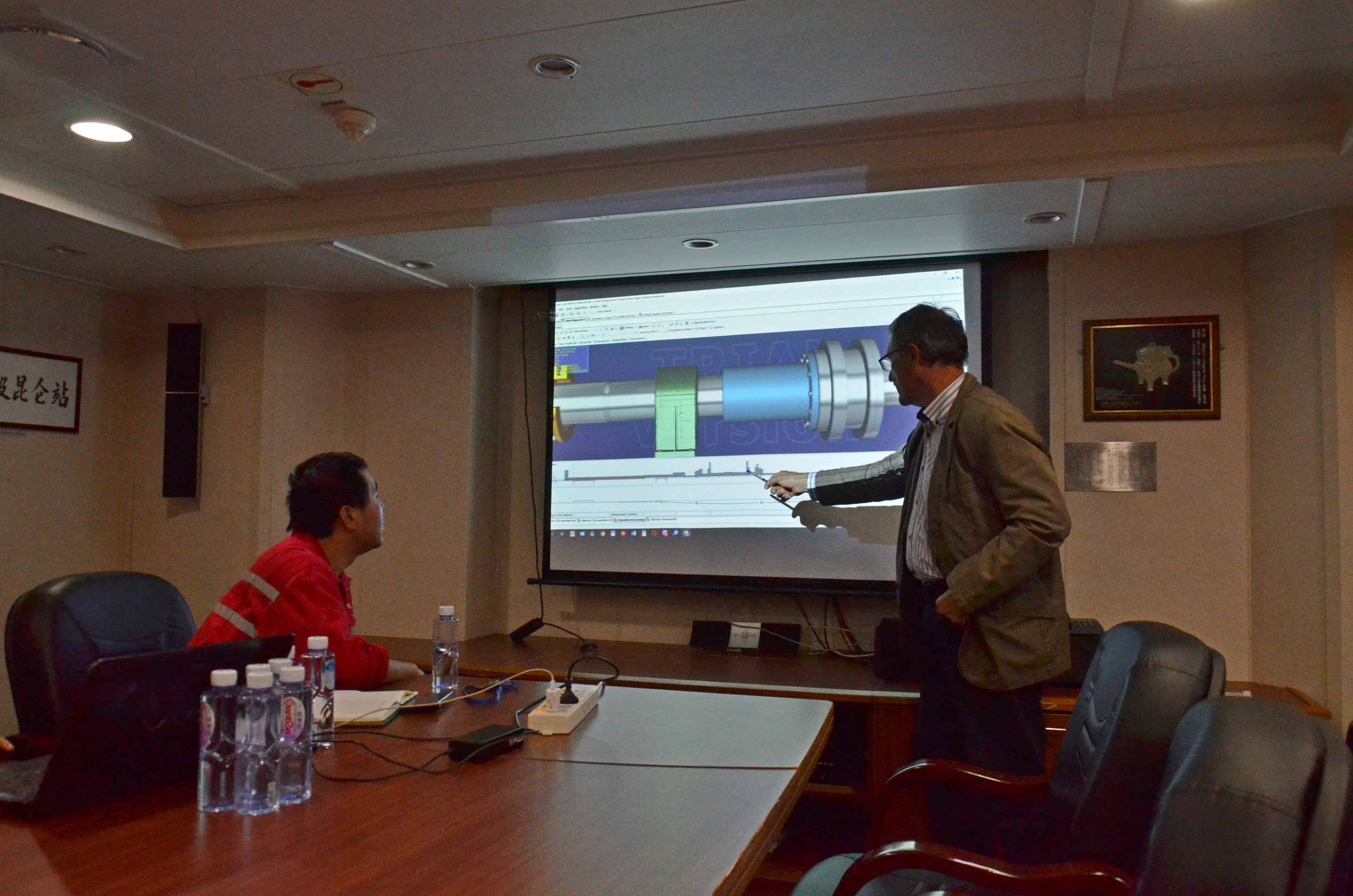

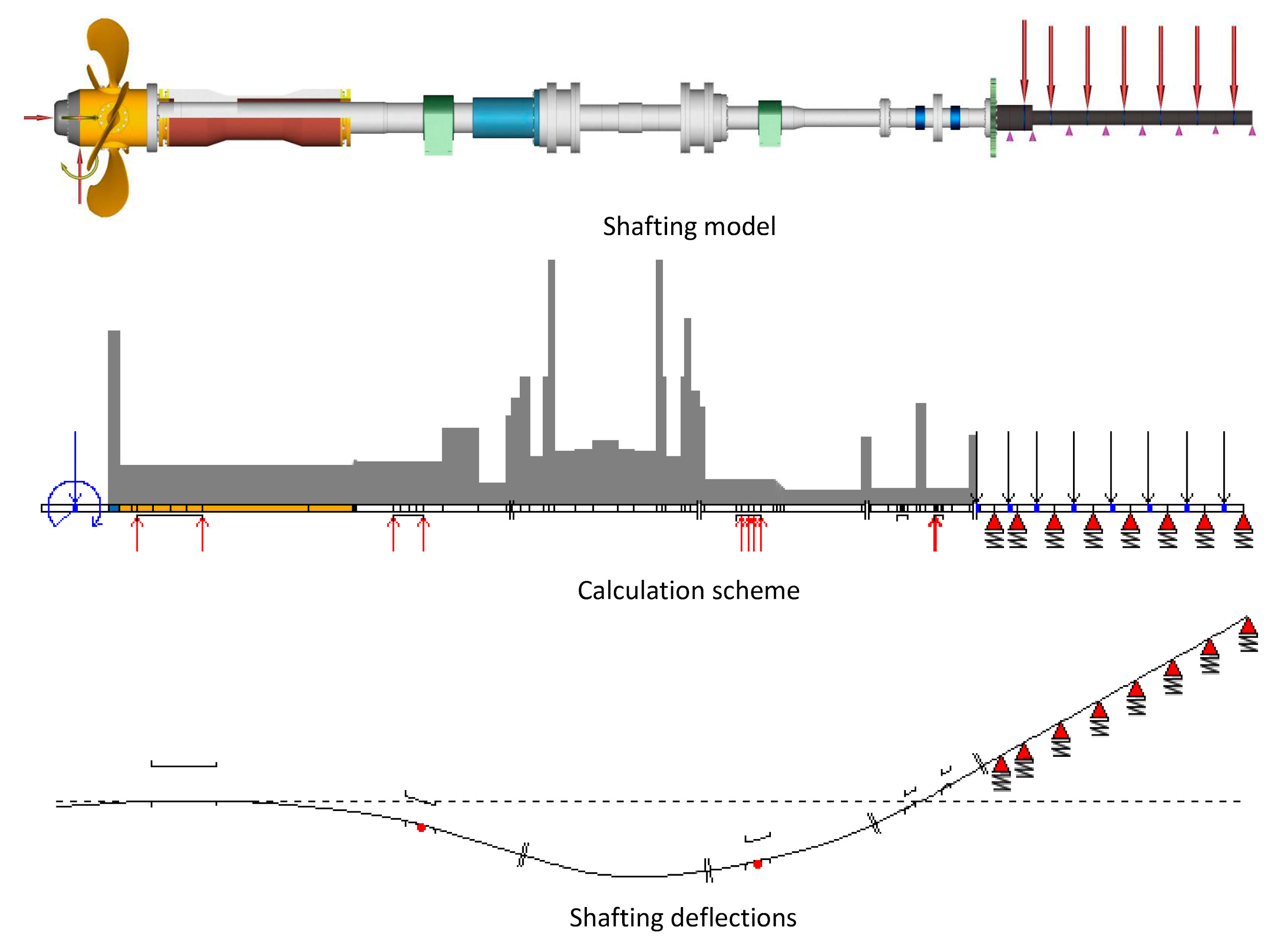

To verify the idea of the bearing failure, our team performed deep comprehensive analysis using the ShaftDesigner software. For this we studied the design and alignment documentation of the shafting, the engine manufacturer measurements performed during the alignment.

The analysis using ShaftDesigner software revealed an unexpected fact that the bearing was 6% overloaded even in normal operating conditions. Studying the available documents concerning shaft alignment, we noticed that according to the old calculations intermediate bearing had only a small margin up to maximum load limit. It should be noted that in this calculation pointwise model for the stern tube bearing was used. When we applied a more realistic extended support model for the stern tube bearing we received the above mentioned 6% overloading.

The specific feature of the Xue Long shafting is single stern tube bearing design, that makes the aftmost intermediate bearing more vulnerable to external loads coming from the propeller. Currently Classification Societies develop special requirements for shaft alignment calculations of the vessels with such type of shafting.

Since the load on the bearing exceeds the maximum limit even under normal operating conditions, it is likely that the ice loads on the propeller that occur during ice milling caused a significant dynamic overload of the bearing. Dynamic bearing overload led to the destruction of the white metal liner surface and caused the deterioration of the lubrication conditions. Further developments were obvious.

After replacing the bearing pads Xue Long went to Antarctic voyage again. During this voyage until now, there were no propulsion shafting issues at Xue Long. It is possible that this time she didn’t meet heavy ice fields.

This case inspired us to start developing a special ShaftDesigner module for ice induced whirling vibration analysis.