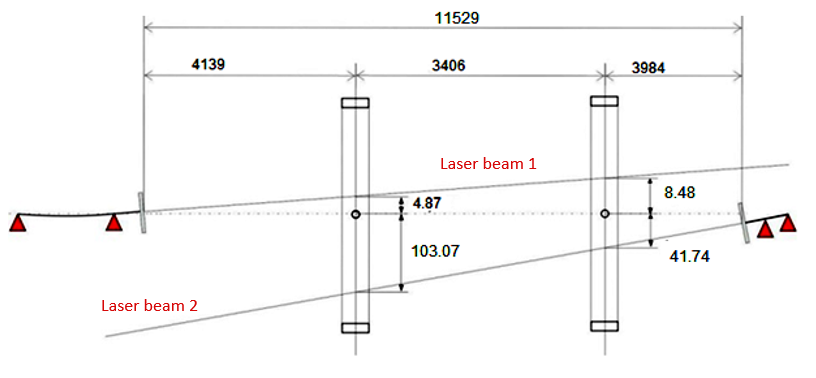

The procedure of the water jet installation shaft alignment was to place the gearbox relative to the main shaft according to developed shaft alignment plan. The spatial position of the gear box was defined taking into account the gearbox manufacturer’s restriction on the loads coming from the shafting. The job looks simple if the distance between the gear box and the main shaft flange is small, but in this particular case it was greater than the allowed laser’s device measurement maximum distance. To solve this problem the alignment procedure with 2 lasers was proposed: the first laser is placed on the main shaft flange, the second one is on the gear box flange. Since the main shaft was considered as a fixed, the intermediate bearings positions were adjusted to obtain the specified offsets. After the intermediate bearings were set properly, the gearbox position was changed to meet the calculated offsets. The idea of two lasers shaft alignment procedure is clear from the following scheme.